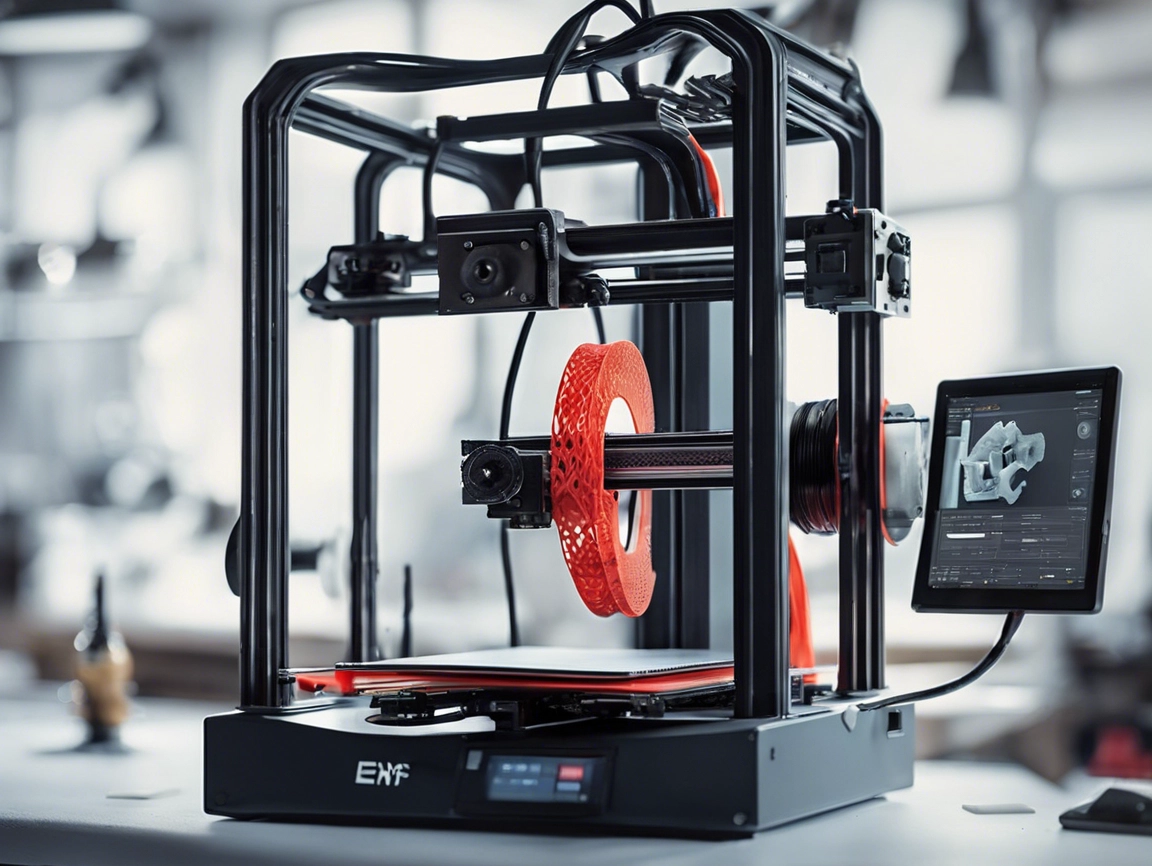

Using 3D printing, the technology that once only produced the products themselves has transformed the entire process into groundbreaking technology. A.I. has been a part of numerous fields; health care, car industry, aerospace to retail industry, even packaged goods. Its challenges: As wonderful as 3-D printing is think customization, reduced waste and rapid prototyping it’s also not so easy.

This article highlights some of the challenges faced by professionals and hobbyists in the 3D printing ecosystem and practical solutions to overcome those challenges. Whether you’re a rookie or an experienced user, a little effort goes a long way to addressing some of these issues, which can greatly enhance your prints.

Material Disqualifications Pick Your Side

One of the enormous challenges in 3D printing is the limited option of materials. There have been advancements in new materials in recent years, but not all of these printers are able to utilize these new materials and the properties of current materials often don’t measure up to expectations.

Challenges:

Printability: Some materials are relatively easier to print (like PLA Polylactic Acid) but don’t have the strength or structural properties needed for some applications.

Material: If you want high-performance materials (e.g., carbon fiber composites or metals), they are prohibitively expensive in single quantities, which normally overwhelms small-scale projects.

Limited Functionality: Many materials are temperature-sensitive, delicate or about out of doors use.

Solutions:

Material Research: Stay on top of innovative materials and what each one of them is designed for. For example, PETG is an excellent middle ground between PLA and ABS with regards to strength and durability.

Prioritize Multi-Use Printers: Look for a 3D printer that can handle different types of materials like flexible or reinforced filament.

Sustainable Choices: Consider 3D printing with biodegradable materials or recycled filaments for a lesser environmental impact.

Print Quality Issues: Potential Fixes

The good thing about 3D printing is that this allows for a more sophisticated aspect to the design. Every now and then you will create horrible prints which could be frustrating. Common problems, especially for beginners, are warping, stringing, and poor adhesion.

Challenges:

Warping occurs when layers cool at different rates, and the edges of your model lift off the print bed.

Stringing, often referred to as unwanted filament threads, due to incorrect retraction settings.

In a 3D print, shifting layers can destroy its beauty and utility.

Solutions:

Bed Leveling: Auto-leveling printer or manual adjustment every so often.

Temperature Friendly: Your printing place is draftless and watching its stability. Enclosures are useful for materials like ABS that are very prone to warping.

Other Settings: Change your slicer software settings (for retraction, speed, layer height, etc.)

Top 3 Printing Troubles and Solutions for Hardware Damages

The best 3D printers are not immune to hardware issues. Things like nozzles, motors and belts and sensors can fail, leading to an incomplete or botched print.

Challenges:

The most frequently discussed problem is blocking of nozzles, which happens almost exclusively when switching materials.

The counterfeit printing press squeezes out hundreds of thousands of runs, the belts wear and make prints a little less acutely accurate, a motor going out will completely kill production.

Solutions:

Routine Care: Clean out the nozzle regularly, check the belts for signs of wear and lubricate moving parts to keep things running smoothly.

Upgraded components: The stock components can be replaced with more capable upgrades, for example, hardened steel nozzles or reinforced belts.

Keep Spares: It’s a good idea to have a fair amount of consumables like nozzles, belts, and build plates for quick replacement.

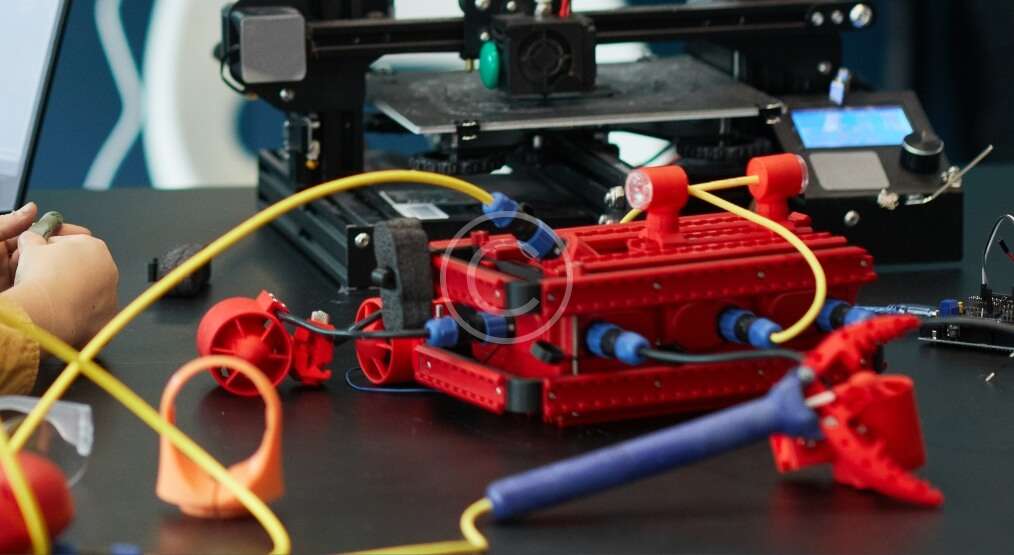

Bringing an Idea to Life, a 3D Printable Model

NGINFCAP is a common cause for this issue as while printing in 3D allows for a great design freedom, it is important to mention that not every design can be printed. Print failures can occur from unsupported overhangs, thin walls and over-complicated geometries.

Challenges:

Overhangs without Support: Designs with long overhangs that are not supported will droop or fail.

Too Thin or Too Thick Walls: If the wall is too thin, it may break easily, but if it is too thick, it will waste material as well as print times.

Unoptimized CAD Models: Even small mistakes in CAD files can lead to major printing problems.

Solutions:

Use DfAM Practices: Make sure that your model follows design-for-additive-manufacturing (DfAM) best practices for 3D printing.

Utilize Specialized Tools: Software such as mesh repair applications can resolve issues in CAD models prior to printing.

Printing Takes Forever: The Balancing Act of Speed and Quality

Printing can take anywhere from a few minutes to several days, depending on the complexity and size of the model. These long print times can lead to scheduling delays and increased costs.

Challenges:

The fact of the matter is that large models or high-detail prints inherently take longer to produce.

In the case of the complex designs slower speeds may be required to assure accuracy.

Printing unattended, or overnight, increases the chances of failure.

Solutions:

Print in Sections: Divide larger models into bits that can be put together later.

Settings you are using: If the parts are not critical, decrease the layer height and infill percentage.

Upgrade HardwareIndustrial printers or printers with larger nozzles can print faster without affecting quality.

Costs Are High: How Can You Get Control of Your Budget?

While 3D printing has the potential to save money, it requires an initial capital investment in the hardware, materials, and software that can be prohibitive. And also, it can add up in maintenance, and the cost of failed prints.

Challenges:

That being said, high-performance printers and materials are also generally priced out of reach for hobbyists.

The learning phase often involves trial-and-error, leading to inefficient resource allocation.

Such industrial-grade applications often incur additional costs for post-processing equipment.

Solutions:

Get Started Small: Investing in the best printers and state of the art materials might be tempting, but it is unnecessary in the beginning.

Reduce Waste: With software you simulate what you are going to print and find out if there is something wrong before starting the real job

Outsource: For occasional or highly specialized projects, an external 3D printing service can eliminate the need to purchase the equipment.

Low Knowledge and Expertise: Connecting the Dots

3D printing is deep science, and stuff you have to know about materials, software, and hardware. Steep learning curves are often a challenge for beginners.

Challenges:

Not understanding it would lead to failed prints all the time.

It can be difficult to know how to start because of the sheer number of printers, materials and software available.

Multi-material printing or post-processing are advanced techniques that require specific expertise.

Solutions:

Engage in Continuous Learning: You can take online classes, watch tutorials, and join webinars to develop your expertise.

Follow Communities: 3D printing forums and local maker spaces provide peer support and suggestions.

Bring In Experts: Work with professionals for more intricate projects.

Novel Solutions in Three Dimensional Printing Technology

The 3D printing industry is evolving quickly with new tools and technologies to solve the most common of challenges:

AI System for Printing: AI systems are helping in doing automatic adjustments for all these settings for quality production.

Advanced Materials: The introduction of new materials including bio-compatible resins, flexible composites, and conductive filaments significantly enhances the range of what can be achieved through 3D printing.

Hybrid manufacturingHybrid manufacturing enables you to combine 3D printing with traditional manufacturing methods, minimizing speed and scale constraints.

Automated Workflow Tools: Cloud–based tools are a way of providing logistical enabling technology for remote monitoring and on line collaboration of 3D printers.

Conclusion

The drawbacks of 3D printing do exist, but they are not impossible to overcome. By preparing properly, keeping up with maintenance, and learning as you go, you can work through these challenges and harness the full potential of 3D printing! Both amateurs and professionals can now work with far superior efficiency and innovation by leveraging new technologies and strategies.

Why are my 3D prints warping, and how do I fix it?

Warping happens when layers cool unevenly. It can be prevented by using a heated bed, adhesion aids, and a stable printing environment.

What are the causes of inconsistent extrusion and how can I troubleshoot?

Make sure the nozzle is not clogged, the filament is loaded correctly, and the extruder presses the filament right.

How do you design advanced designs for 3D printing?

You could split the model into several parts to make printing easier if necessary; In general, Choose design software that checks for printability.

Is 3D printing financially viable for volume production?

For volume, mass manufacturing is more cost-effective and for short runs or most custom items, 3D printing is the best solution.

Can 3D printing be eco-friendly?

Yes, there are biodegradable filaments such as PLA and also recycling systems of used filaments which help to reduce environmental impact.