Is 3D printing going to be a substitute for injection molding? Learn the benefits and drawbacks of both methods, and the role of 3D printing in the future of manufacturing.

Introduction

Over the years, the field of manufacturing has really changed, with 3D printing and injection molding being some of those change factors. Many people are asking the question will 3D printing ever come to replace injection mold technology. In an attempt to resolve this question, we will analyze both features, the offshore strengths of each technology, and the projected industrial perspective as advancement in technology brought in.

What Is 3D Printing?

Also referred to self additive manufacturing, 3d printing is the process of creating a part that entails building materials such as plastic, metal or resin in layers. It makes sense for the model to grow this way since it can be used to produce shapes that are complex and only for small runs or one-off items at a low cost and high speed from a digital templateWhat Is Injection Molding?

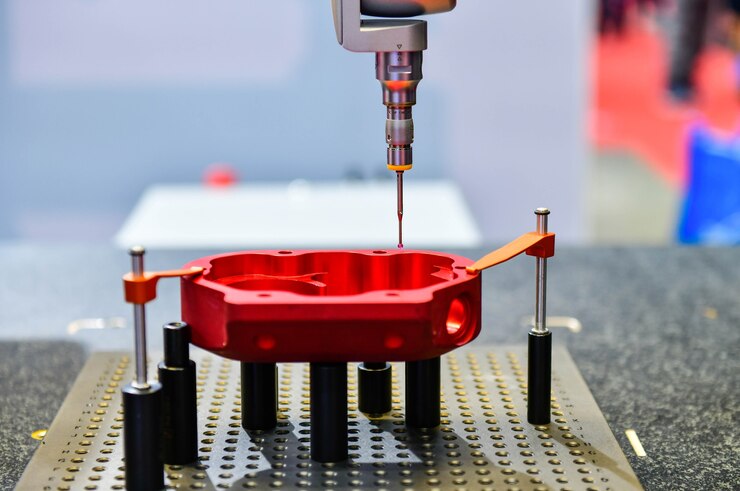

Injection molding, in contrast, is quite a conventional manufacturing technology. It consists of forcing some molten substance into a mold to fabricate an object. This procedure was widely used, for decades, to make high and volume straight and uniformed mass-produced items such as plastic parts, packaging, toys among others.

It is generally acceptable to use this technology to manufacture bulk products because the cost of one piece becomes quite favorable when a large number of units needs to be produced, the technology is very accurate and the reproducibility of the items is excellent.

3D Printing vs. Injection Molding: Key Differences

In the course of carrying out their functions, 3D Printing technology and injection molding processes are endowed with competitive advantages. Here’s how they compare in key aspects:

Speed and Efficiency

3D Printing: Is very ideal for making a small number of production items or for creating a prototype. It takes just hours to get from a digital representation to a physical piece and is therefore very suitable for designs that are likely to undergo numerous modifications.

Injection Molding: While there can be a considerable amount of time required to create the molds to begin the process, once this has been accomplished an enormous quantity of the same parts can be produced within minutes which would be the ideal characteristic for the mass production industries.

Cost-Effectiveness

3D Printing

Due to its low set up cost it can be very cost beneficial when making low production runs. Though, owing to the high per part cost arising out of the mass volume production capabilities in 3D printing setups, such high volume production methods are rarely pursued.

Injection Molding

It is costly to produce the first mold, however, making it a more profitable option for mass production because the total cost per part reduces dramatically in large quantity production.

Will Injection Molding Be Obsolete As a Result of 3D Printing?

Many people have proclaimed the age of 3D printing but are still looking at it as a replacement of injection molding for mass production. However, that wouldn’t be the case as they will be used for different applications.

Let’s look closer

Funds and Volume

In the context of mass production, injection molding is considered to be more cost-efficient and productive. It would be unreasonable for large corporations wanting thousands upon thousands of the same parts to hope for practical 3D printing solutions due to the time and expenses involved.

Physical Properties and Quality of Materials

Even though 3D printing materials are becoming better with time and technology, it cannot be denied that there are some injection molded plastics that possess better strength, durability, and finish.

Speed and Volume Production

The ability of 3D printing to manufacture huge volumes of products will remain incomparable to injection molding. After a mold is developed, it is just a matter of days to manufacture thousands of parts.

Where 3D Printing Sees No Competition

Despite several limitations of injection molding, one thing that can be mentioned is effective areas where 3D printing has no competition would be:

Prototyping

3D printing is widely considered to be the ideal technology for rapid prototyping due to its low costs and quick turnaround times. Engineers and designers are always able to develop ideas which can be polished and advanced before mass production is initiated.

Customization and Personalization

3D printing brings almost infinite opportunities for customization which can be vital when creating special one of a kind products.

Conclusion

So, will the 3D printer one day become the tool of choice over the injection molding process? Not really, to put it simply. Even though the number of tasks performed using 3D printing technology continues to increase, injection molding is at present, very critical for large-scale production. Instead of eliminating one another, these technologies are likely to enhance each other’s performance. Depending on the product type, businesses can opt for either shot molding for large quantities which requires speed and precision or employ the 3D printers for projects that are few and require flexibility and design.

In summary, both 3D printing and molding technologies will be around for a while, offering different perspectives to manufacturing processes going into the future. As they advance, there are likely to be even more avenues to create novel, unique and efficient products that are in line with the consumers’ demands.

Can 3D printing replace injection molding?

No, 3D printing and injection molding are for different things. 3D printing is great for prototyping and small production runs, whereas injection molding is more suitable for high-volume production.

How is 3D printing compared to injection molding which is faster?

Once the mold is made, injection molding does work fastest for mass production. For prototypes or small quantities, 3D printing is typically much faster.

How much does 3D Printing cost compared to injection molding?

Low setup costs at low production run means that 3D printing is economical. It is the most cost-effective way to produce high volumes of plastic parts.

Why is the difference Between 3D Printing and Injection Molding?

As 3D printing can create customized products in less time without the need for molds to create intricate designs.

Is injection molding dead on arrival?

They do not, and injection molding will always be necessary for mass production, simply due to the speed, precision and cost-effectiveness of doing this at high volumes.