San Diego being one of the technological hotspots is going through a manufacturing revolution due to the use of 3D printing. Previously, design thinking strongly shaped the way products were developed, prototyped, and manufactured. As the competition stiffens in the global arena, the application of 3D printing is enabling industries in San Diego to discover new growth paths, from aerospace to even healthcare.

This article considers the role of 3D printing in evolution of manufacturing in San Diego, the implications having this technology, and the sectors which are practicing early adoption.

What Is 3D Printing in Manufacturing?

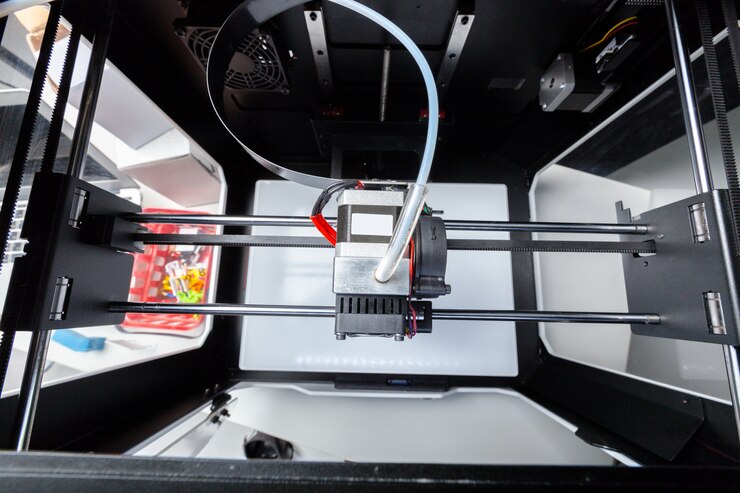

3D printing can also be referred to as additive manufacturing functions by forming objects out of successive layers of plastics, metals, composites and other raw materials. Additive Manufacturing is the disruptive technology that replaces the traditional processes of manufacturing like casting, cutting, and molding. This unique way eliminates the fabrication of molds and producing master patterns directly from CAD/CAM files; thus, offering numerous advantages to companies looking for cost effective and customized solutions to their products reducing lead times.

Exploring the 3D Printing Technology in San Diego’s Manufacturing Industry

San Diego has long been famous for its advanced industries such as aerospace, defense, biotech and consumer goods. These industries now have a greater reason to utilize 3D printing and here is how it is changing the scene: Additionally, the city is home to commercial and residential builders who are now experiencing unprecedented adoption of 3D construction printing within the San Diego area.

Rapid Prototyping

San Diego’s manufacturers are able to fast-track their product designs thanks to 3D printing which conserves costs that would have normally used in outsourcing the product mold. This significantly increases the ability of the business to diversify its products without risking many losses because they can test all production designs before taking them to mass production. This is useful for both nascent companies and established firms.

Custom Manufacturing

3D printing provides a particular advantage in the ability to customize it to create a product targeting a specific audience. From custom manufactured surgical implants to bespoke aerospace components, manufacturers in San Diego do not need to rely on bulk runs and can instead specifically tailor parts to the necessary possibilities. This is extremely useful for sectors that require a lot of bespoke and intricate parts.

Localized Production

San Diego’s manufacturers are now using 3D printing technology to create localized production in order to minimize their reliance on overseas supply chains. This means spending less money on shipping, reduces the amount of time needed to get the products to market, and reduces carbon emissions in manufacturing.

The Contribution of Integrating New Disruptive Technologies

In San Diego, 3D printing is ubiquitous with AI, robotics, IoT among other technologies. As a result, production processes become smarter and more advanced.

Advantages of 3D Printing for San Diego’s Manufacturers

3D technology has several benefits which has increased efficiencies in the Seattle area manufacturing industry. These include:

Saving Money

In most cases, conventional manufacturing techniques are dependent on expensive molds and tooling. The expenses are no longer required because 3D printing is capable of low-cost production over a short period of time and for prototype sampling.

Shortened Supply Lines

Since additive manufacturing only utilizes material that’s essential for the production of a product, waste is much less when measured against subtractive methods such as that of CNC machining.

Getting the Product Out to the Market Faster

The possibility of rapid prototyping and just-in-time production causes shrinkage in the timeline of product conceptualization till getting launched into the market. This is beneficial to companies that wish to beat their competitions.

Increased Creativity

The possibilities of 3D printing have made it so that manufacturers can experiment with previously radical ideas in both designs and form. This spurs innovation and creativity.

Sustainability

3D printing advances green technologies by minimising material waste, permitting decentralised manufacturing and the usage of environmentally friendly materials in its processes.

The Sectors which are Pioneering San Diego

In San Diego, some industries are leading in the use of 3 D printing:

Aerospace and Defense

With a large number of aerospace and defense companies in the area, San Diego is using 3D printing for manufacturing lightweight components, custom parts and rapid prototyping. This technology aids in cost reduction and performance improvement in a very competitive environment.

Healthcare and Biotech

3D printing is being exploited in the production of bio-printed tissues, surgical models, and prosthesis as a result of San Diego’s booming biotech industry. The advancements in medical treatments and research require such exactness and customization that only 3D printing can provide.

Consumer Goods

3D printers allow small companies and entrepreneurs in san Diego to produce tailored-made consumer goods products ranging from innovative home appliances to unique fashion items on demand.

Education and Research

San Diego’s universities and research centers use 3D printing technology for the courses and projects. This promotes invention and prepares the coming generations of engineers and designers for essential activities.

Obstacles and Future Scope

Even when these advantages are apparent, 3D printing is still at a very nascent stage with a lot to cover:

● Material Restrictions: One can note that there have been developments, however, the number of materials used for 3D printing is still very small as compared to conventional techniques.

● Cost of Establishment: There is also the problem of requisite cost of investment when incorporating 3 D printing capabilities.

● Legal Constraints: Some sectors like health care or aerospace should follow a strict policy when it comes to the introduction of 3D-printed parts to their production.

Despite these barriers, the outlook for 3D printing in San Diego is optimistic. Applications for 3D printing services will keep multiplying as technologies are enhanced, costs decreased, and materials improved.

Conclusion

In San Diego, 3D printing changes to the production landscape for the better, creating opportunities that are cheaper, greener, and more numerous across the many sectors. The application ranges from producing reducing time to creating materials which are specific to the market helping the business remain relevant and keep pushing limits. With the increasing trend of San Diegans applying 3D printing, advanced manufacturing continues to be the market San Diego is leading.

If you’re a business owner, an engineer or even a student, the wait is over, whatever 3D printing touches, has huge potential. Endless capabilities mean 3D printing is determination of the future in San Diego and any territory it touches.

In what ways is 3D printing used in aviation in San Diego?

3D printing technology is used in aviation for the light weight structures, bespoke parts and prototypes fabrication which enhances performance while reducing expenses.

Should a small business in the San Diego area make use of 3D printing?

Yes, a small scale enterprise can create custom products, make quick prototypes and lower production costs through 3D printing.

Name the most used materials in 3D printing?

The polymers, metals, composites and bioderived materials are the most common materials used which is dependent on the application and the industry sector.

Can you cite any eco-friendly aspects of 3D printing?

Yes, there is less waste when 3D printing, it helps to produce closer to demand, and can use biodegradable materials which makes 3D printing a viable option.

In which sectors does the use of 3D printing technology in San Diego is expanding?

The sectors implementing 3D printing in San Diego more are aerospace, health, biotechnology, consumer products and education.